Description

Product Description

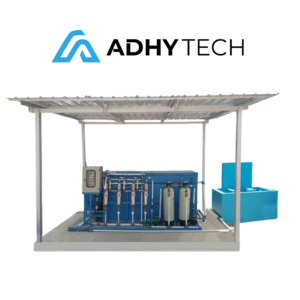

Model Name : iPAL BIO PORT-250

Type : BIO PORTABLE-250MPD

Capacity : 250M³/day

Treatment System : Biofilter (Aerobic & Anaerobic)

Operation System : Automatic – Online Monitoring System

Machinery & Reactor

a) Biostrain Reactor

Main Body

Material : Mild Steel with CNP/UNP framework

Coating : Fiberglass Reinforced Plastic (anti-corrosion, acid-resistant, chemical resistant)

Model : Portable

Filtration : Lamella Clarifier / Bio Ball (anti-corrosion)

Aeration System

Model : Direct Compressed Air

Type : Bubble Coarse Diffuser

Micro Bacteria

Type : Aerobic & Anaerobic

Brand : Abhiotech Bacteria

b) Pre-treatment Systems

Kitchen Liquid Waste Pre-treatment (PTB Kitchen)

Material : FRP

Main frame : FRP

Biomedia filtration separator : PVC (anti-corrosion)

Screen : Anti-corrosion material

c) Laundry Liquid Waste Pre-treatment (PTB Laundry)

Material : FRP

Main frame : FRP

Biomedia filtration separator : PVC (anti-corrosion)

Screen : Anti-corrosion material

d) Chemical Waste Decomposition Treatment (Laboratory Pre-treatment)

Type : Decomposing Chemical Waste Treatment

Model : Automatic Process Precipitator

Multi-stage treatment tank : Mild Steel lined with FRP

pH Adjustment tank : FRP

First-stage filtration : Cartridge Filter

Granular Activated Carbon : Manual backwash

Equipment skid : Epoxy-coated carbon steel

Control panel : Wall-mounted

e) Screening System

Bar Screen : Stainless Steel (perforated)

Fine Screen : Stainless Steel (perforated)

f) Pumps

Supply Pump : Submersible Pump (2 units, 0.75 kW, 1P, 220VAC, 50Hz)

Circulation Pump : Submersible Pump (1 unit, 0.75 kW, 1P, 220VAC, 50Hz)

Distributor Pump : Centrifugal Pump (2 units, 1.5A, 450V, 1P)

Transfer Pump : Submersible Pump (6 units, 750W, 220VAC, 61Hz)

g) Aerator

Type : Ring Blower

Power : 0.75 kW, 1P, 220VAC, 50Hz

h) Chlorinator

Chlorine System

Type : Manual

Material : PVC

Chlorine Tank

Model : Tank

Material : Red Brick / Hebel

i) Water Meter

Model : Flow Meter

Type : Magnetic Water Meter (Analog Display)

j) Control Panel

Main Control Panel : Indoor/Outdoor with online monitoring (Mild Steel Powder Coating, 0.1 kW power)

Local Panel : Indoor/Outdoor (Mild Steel Powder Coating)

Civil & Construction Works

Construction Work

Wastewater piping system : Interconnection system (anti-corrosion)

Water interconnection : PVC

Electrical network cables

Civil Work Specifications

Control tank (5 units)

Sump pit (1 unit)

Main processing machine foundation (1 unit)

Laundry PTB machine foundation (1 unit)

Kitchen PTB machine foundation (1 unit)

Laboratory MHP machine foundation (1 unit)

Equalization tank (1 unit)

Indicator tank (1 unit)

Main machine fence (1 unit)

Landscape (1 unit)

Services

Commissioning : Installation of bacteria & startup tools

Installation : On-site optimal setup

Independent Training : On-site training (PPA & POPAL)